|

||||||||||||||||

Haas cooling options offer greater productivity, better finish and longer tool life

Zaventem, Belgium. February 2015: One of the primary challenges in modern machining is keeping the tool lubricated and ensuring chips are removed from the cutting zone. Failure to do so can lead to a multitude of problems, including premature tool wear and damage.

The Haas Flood Coolant Ring, which is standard on all VM and VF series Haas machine tools, provides a cascade of coolant that thoroughly lubricates the cutting area, while dispersing chips produced during cutting.

The coolant ring concept is a significant improvement over traditional hose-based systems. The ring’s fully adjustable nozzle tips direct precision coolant flow to the tool from many angles. The nozzles are easy to move, and the ring is positioned for maximum clearance and ease-of-use.

While the Flood Coolant Ring serves as the main Haas coolant delivery system, numerous other cooling options are available. For instance, the Haas Programmable Coolant Nozzle, or P-Cool, can take up numerous positions to serve any tool selected, long or short.

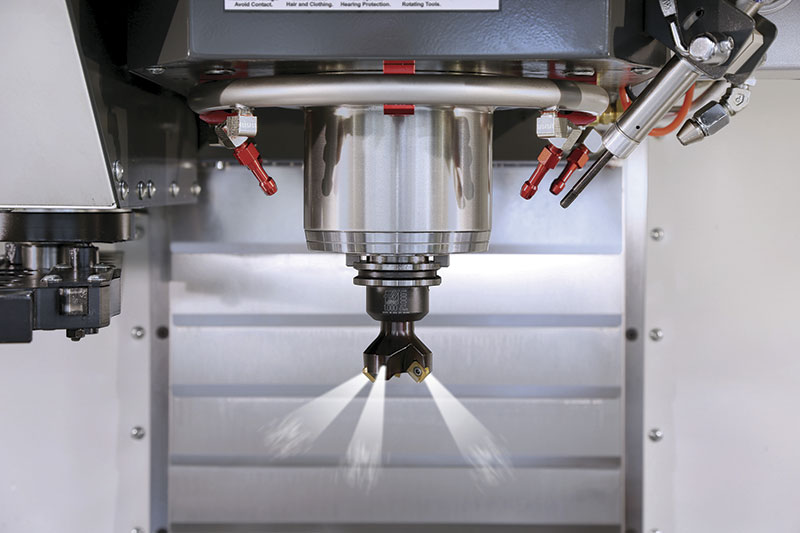

Another effective method of getting coolant to the cutting zone is to deliver a high pressure blast through the tool tip. Here, the Haas Through-Spindle Coolant (TSC) system, which is particularly effective when drilling deep holes or milling deep pockets, is available in either 300 or 1000 psi (20 or 70 bar) configurations.

For machine shops using modern carbide tools with advanced coatings to cut materials in a dry environment, there is significant potential to recut chips not evacuated from the cutting area (a primary contributor to early onset tool wear). To overcome the issue, Haas offers an optional Through-Tool Air Blast system (as an add-on to the TSC system) that removes chips from the machining zone before they can be cut a second time. This is particularly useful for deep cavity machining.

Serving a similar function is the Haas Auto Air Gun. This system is ideal when using small tools that are not suitable for through-tool air delivery. The Haas Auto Air Gun is also a great complement to the Through-Tool Air Blast system in demanding dry machining applications that require a higher volume of air delivery.

Last but not least, for applications where coolant cannot be deployed, but the tool still needs to be kept lubricated, the new Haas Minimum Quantity Lube option provides the solution. This innovative system works by atomising a precisely metered quantity of lubricant into the air stream and delivering it to the tool’s cutting edges. The quantity dispensed is typically very small, to the extent that it’s invisible.

Among the major advantages of the Minimum Quantity Lube system is that it uses just a fraction of the coolant deployed in typical flood-based applications. Furthermore, the air and coolant flows are controlled separately, which means users can adjust the ratios to best suit their specific application.

Ultimately, Haas machines offer many effective ways to maintain performance in the cutting zone. The company is more than happy to help customers assess specific applications so that the best options can be selected.

For further information please contact:

MBMC – International Press and Publicity

+44 (0) 1603 283 601

« Назад

|

|

|

|

|

Copyright © ТЕХСОВЕТ премиум 2003-2024

|

|||