Æóðíàë ÒÅÕÑÎÂÅÒ ïðåìèóì

Zaventem, Belgium. March 1st, 2015: The late 1990s were not an easy time in the life of the young Danijel Bertol. The Croatian War of Independence had raged for 4 years, ending finally in 1995 with the country ravaged. Then, just 2 years later, his father died unexpectedly, leaving his small machining business idle and the family, like so many in the country at that time, to rebuild their fractured lives.

Danijel, then 24, was at college reading engineering. But after completing just two years of his studies, he ditched his books and returned home to Velika Mlaka on the southern outskirts of Zagreb, with the intention of picking up where his late father had left off. With the blessing and support of his mother, Danijel began plotting an ambitious future for the company.

“Croatia was in a period of rebuilding after the war, with a lot of new buildings using glass,” Danijel says. “So, it seemed to me like a sector with some potential. I began to

research, design, and manufacture glass fittings. Although I had no experience in this particular field, I used to help my father in his garage, operating the machine tools, so I knew enough to get started on making some prototypes”

A little after 2003, the resurrected Bertol company was in full swing, but Danjiel understood that growth would be limited severely if he didn’t invest in some new, better-quality CNC machine tools to replace the manual machines he grew up watching his father operate.

“I knew we would not be competitive enough, so the decision was taken to invest in a new machine, even though it would represent a significant financial commitment,” he says. “At first, we considered pre-owned machines, but then my teacher from high school said it would be good to buy new machines, and he proposed Haas. He had left teaching to run his own engineering business using Haas machines, and he had nothing but good things to say about them and the local Haas Factory Outlet (HFO), Teximp.”

Bertol’s first Haas machine, a VF-1 vertical machining centre, arrived in 2005. Since then, the company has added a larger VF-2 vertical machining centre and four Haas turning centres, including two ST-10 models that arrived in 2014.

“Every time we are about to invest in new machines, we sit down and assess the market and what’s available for the money,” says Danijel. “When we put everything on the table and go through the specification and performance of the alternatives, Haas is always the best all-round offer.”

If 2015 goes well, Danjiel will invest in Haas again, this time with his eye on a new VF-3 vertical machining centre. Like the company’s existing Haas machines, the new machine will be set to work producing the company’s growing range of innovative, contemporary glass fittings, which includes clamps, handles, knobs, levers, point fixings, and flexible joints, as well as system fittings for showers, balustrades, and sliding and rotating doors. In all, Bertol currently offers around 500 different part types, 90 percent of which are machined from high-quality stainless steel.

“In terms of accuracy, we can achieve 0.01 to 0.02 mm using the Haas machines. But typically, aesthetics are just as important as precision in our industry – the products have to look good to match the high specification commercial and residential projects with which we are associated,” says Danijel. “Virtually everything we do is bespoke; we work closely with the customer to devise optimum solutions that look nice and can be installed easily and quickly.”

Today, Bertol has 10 employees, four of whom are trained to program the Haas machines (“Our team is our most important asset,” says Danjiel). And it’s not just Croatian customers who have discovered Bertol’s innovation and machining skills: around 60 percent of the company’s output is now exported, with most of it going to Germany.

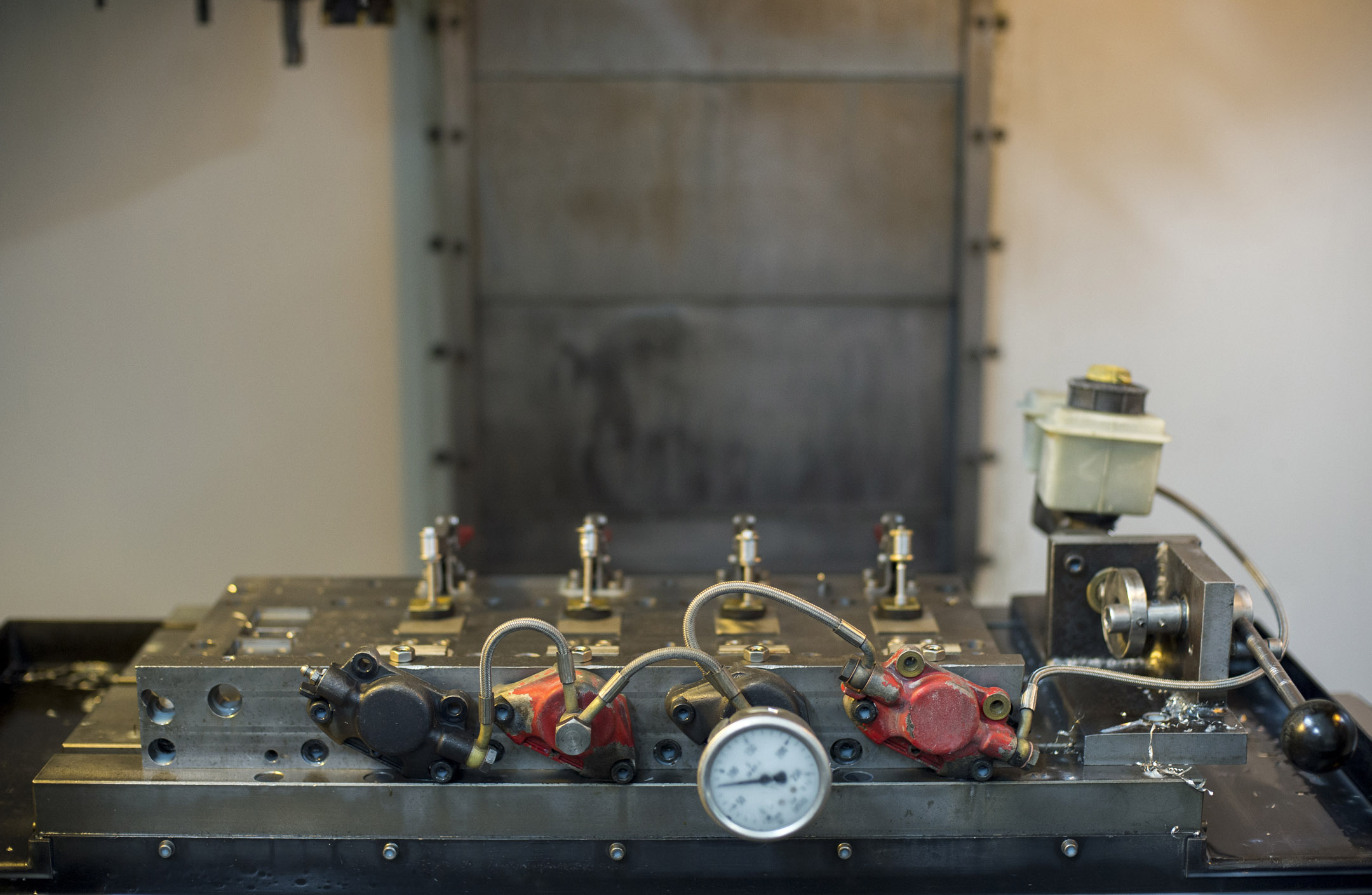

“Buying the Haas machines has proved to be 100 percent a good decision for us,” says Danijel. “Moreover, we get excellent support from Haas Factory Outlet, Teximp. In fact, our sales contact at the HFO, Nenad Macan, even came up with a very novel and effective solution for part holding on one of the Haas machining centres. The multi-component, quick-release fixture we made in-house uses motorcycle brake calipers hooked up to a mini hydraulic system. It’s simple, low cost, very reliable and works a treat!”

Ultimately, Danijel sees his company not as a large organisation producing thousands of standard parts, but as a creative business that can offer great flexibility in its product line. Bertol is already earning a reputation for being able to accommodate a huge variety of customer requirements, as well as short delivery times.

Not many people begin their journeys to business success from such national and personal low-points – in the aftermath of war and family loss. But perhaps because of these hardships, Danijel Bertol embodies an uncommon energy: a sense of opportunity and destiny. Now that Croatia is part of the EU, he and his contemporaries can look forward to a more secure future.

The company's motto: In Metal We Trust

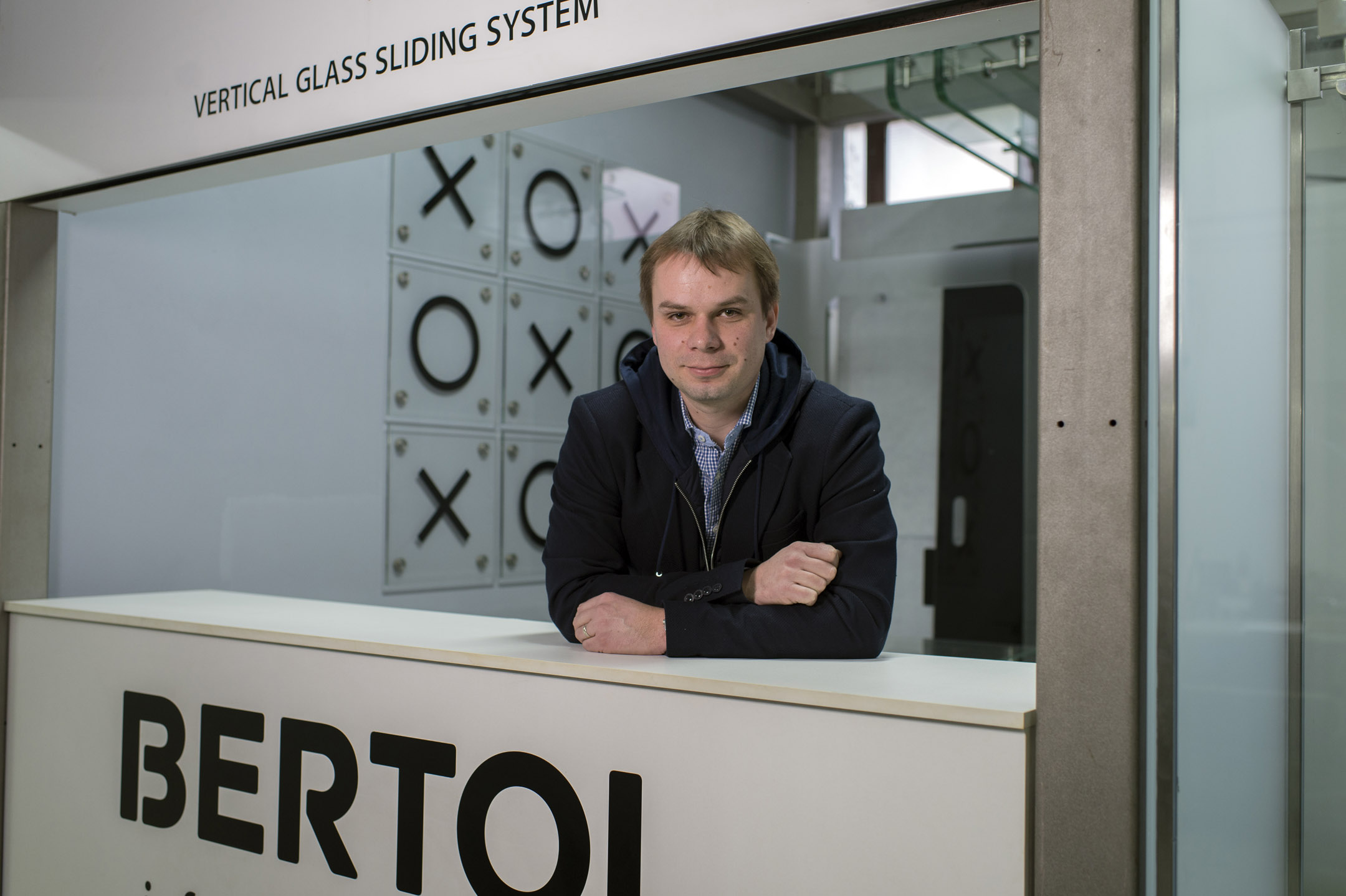

Danijel Bertol took over the running of his family business, Bertol, in 2003

Bertol’s first Haas machine, a VF-1 vertical machining centre, arrived in 2005. Since then, the company has added a VF-2 vertical machining centre and four Haas turning centres, including two ST-10 models

The Haas machines produce the company’s growing range of innovative, contemporary glass fittings, which includes clamps, handles, knobs, levers, point fixings, and flexible joints, as well as system fittings for showers, balustrades, and sliding and rotating doors

Hydraulic fixtures used on the Haas VMCs are made in-house and use motorcycle brake callipers to regulate pressure.

A Bertol hinge component used for architectural glass fittings

END

For further information please contact:

MBMC – International Press and Publicity

+44 (0) 1603 283 601